What do you want to package?

Featured Products

Latest News

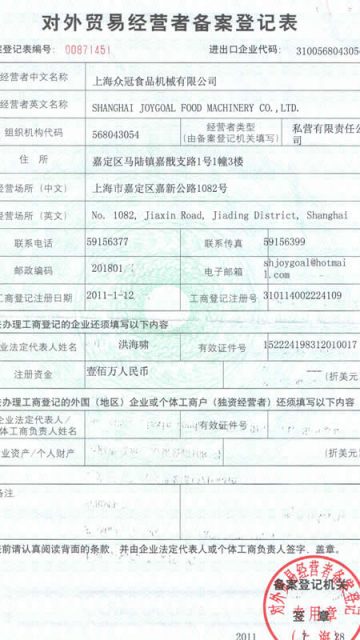

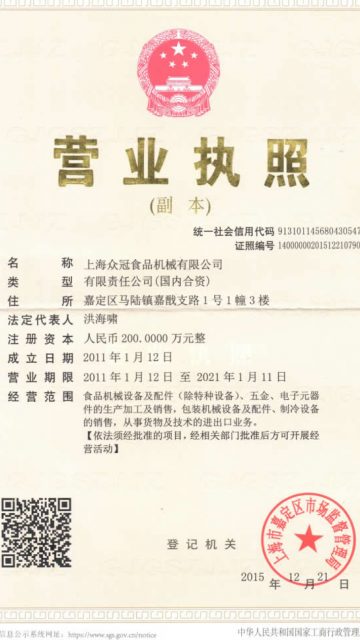

China Filling Machine, Packing & Packaging Machine Manufacturer

Simple, Efficient Packing Machines to Meet Your Needs

Let us help you overcome your toughest packaging automation challenges with intuitive, easy-to-use equipment.

Whether your packaging needs are leading edge or more traditional, JOYGOAL Machinery has a solution. Are you looking to improve ROI in your production and packaging processes? We can show you how with automation. And if you’re simply upgrading existing machines or know exactly what you want, our superior quality equipment provides a powerful solution that can be adapted to meet your needs.

Flexible packaging offers many benefits over its rigid counterpart, including a decreased carbon footprint, savings on shipping and storage, and a more prominent shelf-presence and a larger canvas for marketing. Applicable to almost every industry, both food and non-food, flexible packing machines increase both efficiency and your bottom line.

Vertical Form Fill Seal

Vertical form fill seal packaging machines are flexible, allowing manufacturers to pack almost anything into a variety of bag styles.

Pouch packing machine

Streamline your operations and improve output by up to 50 percent using our premade pouch packing machines. Contrary to our vertical form fill and seal machines that uses roll stock picture to make bags, our semi automatic pouch packaging machines provide something entirely different.

Simple, Efficient Filling and Sealing Machines to Meet Your Needs

A versatile machine which packs an almost unlimited range of different products into bags delivering high performance and reliability. Forming, filling and sealing in a single work process.

JOYGOAL has unique expertise in the design and manufacture of filling and sealing machines for food products in preformed pots. All our filling and sealing machines are equipped with the anti-drip filling nozzle for a perfect control of the product textures.