Liquid Packaging Machine

1. Features of vertical packing machine

2. The use of vertical liquid packing machine

Liquid packaging machines are packaging equipment for packaging liquid products, such as beverage vertical packing machine for sauce, dairy filling machines, viscous liquid food packaging machines, liquid cleaning supplies and personal care packaging machines, etc. It belongs to the category of liquid packaging machines.

It is suitable for liquids such as soy sauce, vinegar, juice, milk, etc. It adopts 0, polyethylene film, forming, bag making, quantitative filling, ink printing, sealing and cutting are fully automated, and the film meets the requirements of food hygiene before being sterilized and packaged by ultraviolet rays.

3. What is the difference between a filling machine and a packaging machine?

vertical jam packing machine, I believe everyone will be relatively vague, and now I will give you a clear introduction. There are many types of filling machines, which can be divided into atmospheric filling machines, pressure filling machines and vacuum filling machines according to the filling principle. These three filling machines are widely used. For example, the normal pressure filling machine fills according to the weight of the liquid under normal pressure, the pressure filling machine fills under normal pressure, and the vacuum filling machine fills under the pressure inside the bottle is lower than the normal pressure filling. The functions of the three are different. Atmospheric pressure filling machines are divided into two types: timed filling and constant volume filling. It is only suitable for filling low-viscosity, gas-free liquids such as milk and wine; pressure filling machines can also be divided into two types: one is isobaric filling, and the other is that the pressure in the liquid storage tank is higher than that in the bottle. pressure, the liquid flows into the bottle by the pressure difference. Liquid filling of gas, such as beer, soda water, champagne, etc.; vacuum filling machine has simple structure, high efficiency, and can adapt to a wide range of viscosity of materials, such as oil, syrup, fruit wine, etc. Fluid products such as juice, jam, honey, ketchup, shampoo, liquid, pesticide granules, edible products, electronic components and other products. Made of stainless steel, it can well ensure the hygiene and safety of the product.

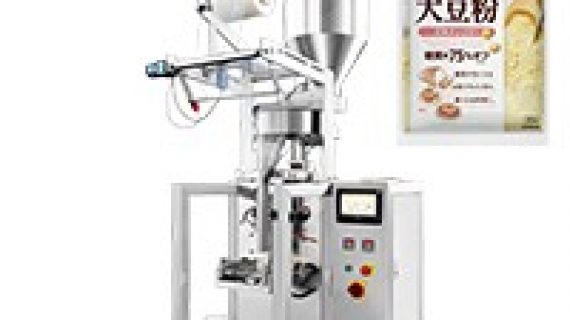

Second, the principles and characteristics are different. The filling machine has simple operation process and small precision error. It is very convenient in installation and adjustment, equipment cleaning and maintenance. The filling and lifting system, positioning system and liquid level control system of foam products ensure the positioning of the bottle mouth. The vertical liquid/paste curd packing machine is generally made of stainless steel, equipped with a high-level balance tank or self-priming pump for quantitative filling, direct heat sealing and cutting, and convenient and reliable adjustment of bag size, packaging weight, and sealing and cutting temperature.

It is not difficult to see the difference between a high speed vertical 4 side seal shampoo pouch liquid sachet packing machine and a small liquid vertical packing machine. Not only principles, features, uses, etc… So we must choose suitable products and equipment for our own enterprises when purchasing. vertical auger screw packing machine brand.