Some basic knowledge about automatic stand up pouch filling and capping machine

–How to choose a suitable stand-up pouch filling and capping machine

Recently, many friends asked me some questions about how to choose the automatic stand up pouch filling and capping machine (hereinafter referred to as stand up pouch filling machine), and I did some sorting on some common problems.

- What is a stand-up pouch?

- What factors will affect the design of the stand-up pouch filling machine?

- What kind of product is the spouted pouch filling capping machine suitable for?

- What are the types of stand up pouch filling capping machines?

- How to choose a spout pouch filling and capping machine suitable for you?

- How to realize the function of the printing date?

- Is there any video of a spout pouch filling machine?

- What is the price of the stand-up pouch filling and cap-screwing machine?

- What are the manufacturers of daypack pouch filling machine?

- What is a stand-up pouch?

stand up pouch (doypack) is a kind of soft packaging bag with a horizontal support structure at the bottom. It can stand on its own without any support. According to whether there is a suction nozzle, it can be divided into a stand-up pouch with spout (suction nozzle) and a stand-up pouch without spout (suction nozzle). The stand-up pouch with spout is also known as the spouted pouch because this spouted pouch can stand on its own, and it looks like a penguin, so it can also be called a penguin bag. A self-supporting bag is also a common form of packaging on the market.

- What factors will affect the design of the stand-up pouch filling machine?

There are many kinds of stand up pouch (doypack) on the market because the stand-up pouch filling machine is mainly designed according to the spout of the stand-up pouch, so the structure of spout (suction nozzle) is very important for the design.

I) The slot of the spout (suction nozzle) has a single layer or a double layer. The method of pouch loading corresponding to the single-layer slot or the double-layer slot will also be different. The following picture shows two different pouch loading structures corresponding to two different spout (suction nozzle) on the machine.

II) The cap will have different structures. When the cap’s size and structure are different, the cap screwing structure should be designed accordingly. For example, the design of the screw head corresponding to the common cap and the large head cap is totally different, as shown in the figure:

III) The filling capacity of the stand-up pouch filling machine is designed according to the volume of the bag. Generally speaking, the maximum adjustable capacity of the machine is 20% more than the volume of the pouch. The filling capacity of the stand-up pouch filling machine can be adjusted according to the needs, but the adjustment range should not be too large. For example, it is not suitable to use the same filling system for 50ml and 500ml capacity, because the 500ml filling system is not accurate enough when filling 50ml.

- What kind of products is the stand-up pouch filling and capping machine suitable for?

The full-automatic stand up pouch filling and capping machine is also called doypack filling and sealing machine. As the name implies, it is mechanical equipment integrating the filling and capping functions of stand up pouches. Usually, this machine can fill filling fluid, semi-fluid, paste, and other different forms of materials, such as soy milk, tomato paste, laundry liquid, water, suction jelly, and so on.

According to the status of different materials, the corresponding filling method should be designed.

- What are the types of stand up pouch filling and capping machines?

According to the introduction of JOYGOAL, the stand-up pouch filling and capping machines suitable for industrial production are divided into two categories according to the degree of automation:

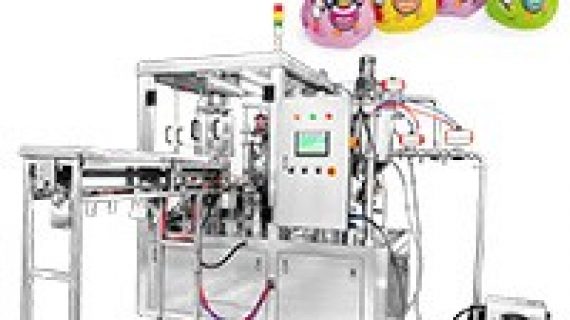

ZLD-A series automatic stand up pouch filling and capping machine

ZLD-A series automatic stand up pouch filling and capping machine has the highest degree of automation. The equipment includes the functions of automatic bag hanging, bag free detection, automatic filling, automatic capping, automatic capping, automatic capping, uncapped detection, automatic capping, and automatic finished product output. The advantages of ZLD-A series filling and capping machine are high degree of automation, including multiple fault alarm systems, which can monitor the operation of the equipment in real-time through photoelectric detection and PLC control. Secondly, the automatic cover turning function adopts a constant magnetic torque device, which can keep the torque constant, so as to ensure that the tightness of the cover of the same batch of products is consistent.

ZLD-B series semi-automatic stand up pouch filling and capping machine

The automatic level of ZLD-B series semi-automatic stand up pouch filling and capping machine is slightly low, which is the experimental equipment used in early small factories. The functions of this series of machines are automatic filling, automatic Liding, automatic cover covering, automatic cover rotating, and automatic production of finished products. Compared with the A-Series model, the B-series model lacks the automatic bag feeding support and the automatic bag hanging function, so it is necessary to manually hang the bag on the turntable of the equipment. It can be seen that the capacity of the B series of stand up pouch filling and capping machine depends on the speed of manual bag hanging.

- How to choose a stand-up pouch filling and capping machine?

First of all, we should determine the form of packing. Each stand up pouch filling and capping machine can be applied to the same suction nozzle bag. Keep the suction nozzle structure of the stand-up pouch unchanged. When the shape or capacity of different bags changes a little, it can be used in the same stand-up pouch filling and capping machine.

Common suction nozzles are as follows:

Secondly, we need to calculate the actual production capacity we need. The following table shows the actual production capacity of the ZLD-A series of stand up pouch filling and capping machines when filling fluid.

The model number of filling head capacity (bag/hour)

| Model | Filling nozzle | capacity(pouch/hr) |

| ZLD-1A | 1 | 800-1000 |

| ZLD-2A | 2 | 1600-2000 |

| ZLD-3A | 3 | 2400-3000 |

| ZLD-4A | 4 | 3200-4000 |

| ZLD-5A | 5 | 4000-5000 |

| ZLD-6A | 6 | 4800-6000 |

What we should pay attention to is that when our filling materials are poor fluidity or easy to generate foam, the capacity of machine design will decrease. At this time, it is suggested to ask the technical personnel for some professional suggestions.

- How to print the date on the stand-up pouch?

In the early actual production process, many factories are through the purchase of inkjet printer, through manual printing in advance on the bag date. This brings about the waste of labor, in today’s rising labor costs, how to save labor has become particularly important.

There are usually two ways to solve this problem:

One is to install the printer directly on the machine. The coding machine can be installed in the filling station before the bag is filled to print the date. Due to the space limitation, the coding machine is usually applied to the machines of ZLD-1A and ZLD-2A, as shown in the figure:

The other is to install the inkjet printer on the filling and capping machine. The inkjet printer is also installed in the station before filling it. Due to the small size of the nozzle of the inkjet printer, it is suitable to be installed on the filling and capping machines of ZLD-1A to ZLD-6A models. As long as the bag passes through the printer head, the date can be printed, as shown in the figure:

- Where can I view the video of the stand-up pouch filling machine?

The following website (YouTube) can view many videos of different models of stand up pouch filling machines.

http://www.youtube.com/c/ShanghaiJoygoalFoodMachineryCoLtd

- What is the price of a stand-up pouch filling machine?

The stand-up pouch filling machine is customized according to the requirements of customers, so the price fluctuates according to the design and requirements of the machine. Generally speaking, the price of an ordinary stand up pouch filling machine with standard functions is between 20,000-30,000 US dollars.

- What are the manufacturers of stand up pouch filling machine?

Shanghai JOYGOAL Food Machinery Co., Ltd. is a professional manufacturer of stand up pouch filling machine. Located in Shanghai, with more than ten years of manufacturing experience, it is an early manufacturer of such equipment in China.

SHANGHAI JOYGOAL FOOD MACHINERY CO., LTD