The box chafing dish dipping and sealing machine sublimates the chafing dish once again

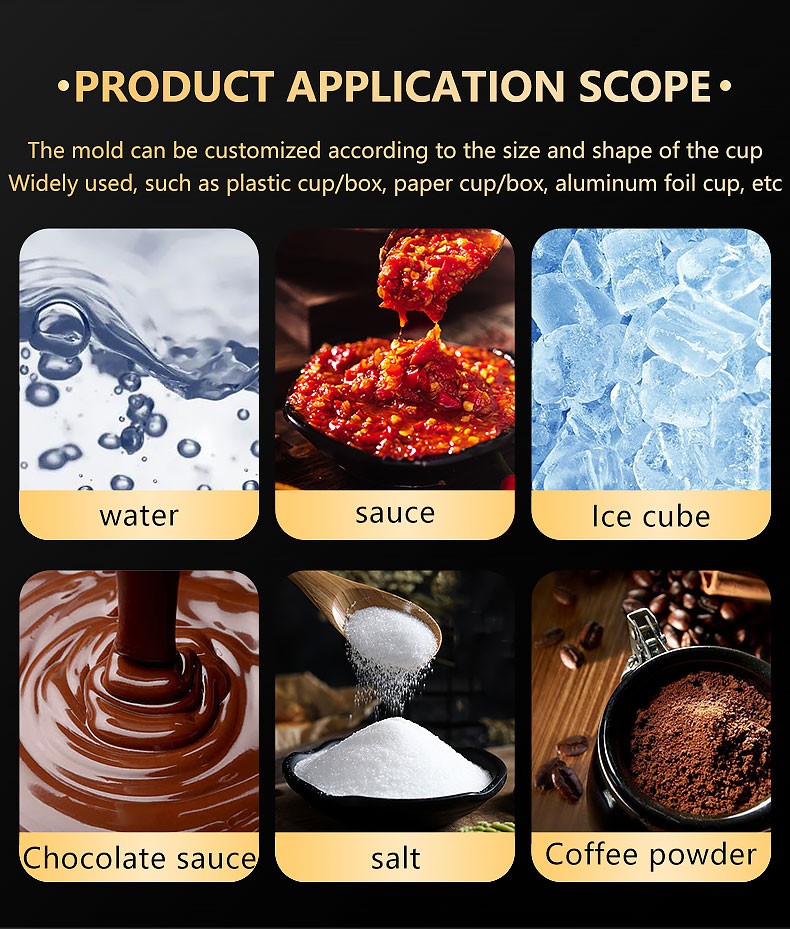

. Chafing dish is a more popular kind of delicacy in every season, especially in the cold winter. There is a heavy snow outside, and our family is gathered together, the soup was so thick that we could not see each other faces through the hot air, but we could feel the smile on our faces as we drank hot water and cooked mutton with chopsticks. After the dishes are rinsed, they are dipped in hot pot dipping sauce, which is even more delicious. The hot pot dipping sauce sold in the market today has all kinds of flavors, including garlic, spicy and spicy, etc. , and for these boxes of hot pot dip packaging, we need boxes of hot pot dip sealer equipment, with the existence of this equipment, is really for hot pot cuisine once again sublimated. Box chafing dish dip sealing machine is a new generation of filling and sealing machine equipment, box chafing dish dip sealing machine touch screen computer system control, one machine system more stable, simpler operating system. And equipment using 304 stainless steel, hard acid-resistant aluminum alloy, beautiful generous, good cleaning. This box chafing dish dip sealing machine drop cup, measuring, filling, sealing, coding, packaging automatic molding, suitable for a variety of materials or containers packaging use. At present, the box hot pot dip sealing machine in a number of industries, many products are widely used in the production. Hot Pot has been loved, it directly affects the development of hot pot dip product market, will follow the prosperity of hot pot and have an invincible position. More along with the condiment filling now more and more towards diversification, health and environmental protection, personalized, small batch development. More and more companies are making one-person sauces, thus making life easier for us, whether it is to pack, take-away, at home, or in a hotel.

. Chafing dish is a more popular kind of delicacy in every season, especially in the cold winter. There is a heavy snow outside, and our family is gathered together, the soup was so thick that we could not see each other faces through the hot air, but we could feel the smile on our faces as we drank hot water and cooked mutton with chopsticks. After the dishes are rinsed, they are dipped in hot pot dipping sauce, which is even more delicious. The hot pot dipping sauce sold in the market today has all kinds of flavors, including garlic, spicy and spicy, etc. , and for these boxes of hot pot dip packaging, we need boxes of hot pot dip sealer equipment, with the existence of this equipment, is really for hot pot cuisine once again sublimated. Box chafing dish dip sealing machine is a new generation of filling and sealing machine equipment, box chafing dish dip sealing machine touch screen computer system control, one machine system more stable, simpler operating system. And equipment using 304 stainless steel, hard acid-resistant aluminum alloy, beautiful generous, good cleaning. This box chafing dish dip sealing machine drop cup, measuring, filling, sealing, coding, packaging automatic molding, suitable for a variety of materials or containers packaging use. At present, the box hot pot dip sealing machine in a number of industries, many products are widely used in the production. Hot Pot has been loved, it directly affects the development of hot pot dip product market, will follow the prosperity of hot pot and have an invincible position. More along with the condiment filling now more and more towards diversification, health and environmental protection, personalized, small batch development. More and more companies are making one-person sauces, thus making life easier for us, whether it is to pack, take-away, at home, or in a hotel.