More optional features

- Caps feeder to feed caps to ZLD-4A automatic spout pouch filling and capping machine

- Whole machine made of stainless steel

- Air clean system

- Open dust cover door detector to keep production safe

- CIP system fit for ZLD-4A

- Conveyor belt to transport finished pouches

- Printing machine to print date or lot numbers

- Air compressor to supply compressed air for ZLD-4A running

- Stainless steel pump to feed product to ZLD-4A automaic

- More spare parts

- Nitrogen generator to supply nitrogen for ZLD-4A

Support

- Detailed user’s manual

- Detailed video of showing machine installation and operation

- Detailed pictures of showing how to adjust machine’s speed, how to adjust filling volume, how to adjust strength of vibrating, how to adjust strength of capping, how to maintance

- After sale response time less than 6 hours

- ……

- Factory and manufacturer directly sales with competive price

- More than 8 years experience of design, manufacturing

- Touch screen in English and Chinese languages

- Two emergency stop buttons to keep production safe

- Detections: no pouch no filling, no cap stop, vibrator run automatic

- Dust cover, ultraviolet sterilization lamp

- Professional designers and workers to serve you

- This machine with a strict inspection before out of storage

- Food grade 304# stainless steel is used in our spout pouch filling capping machine

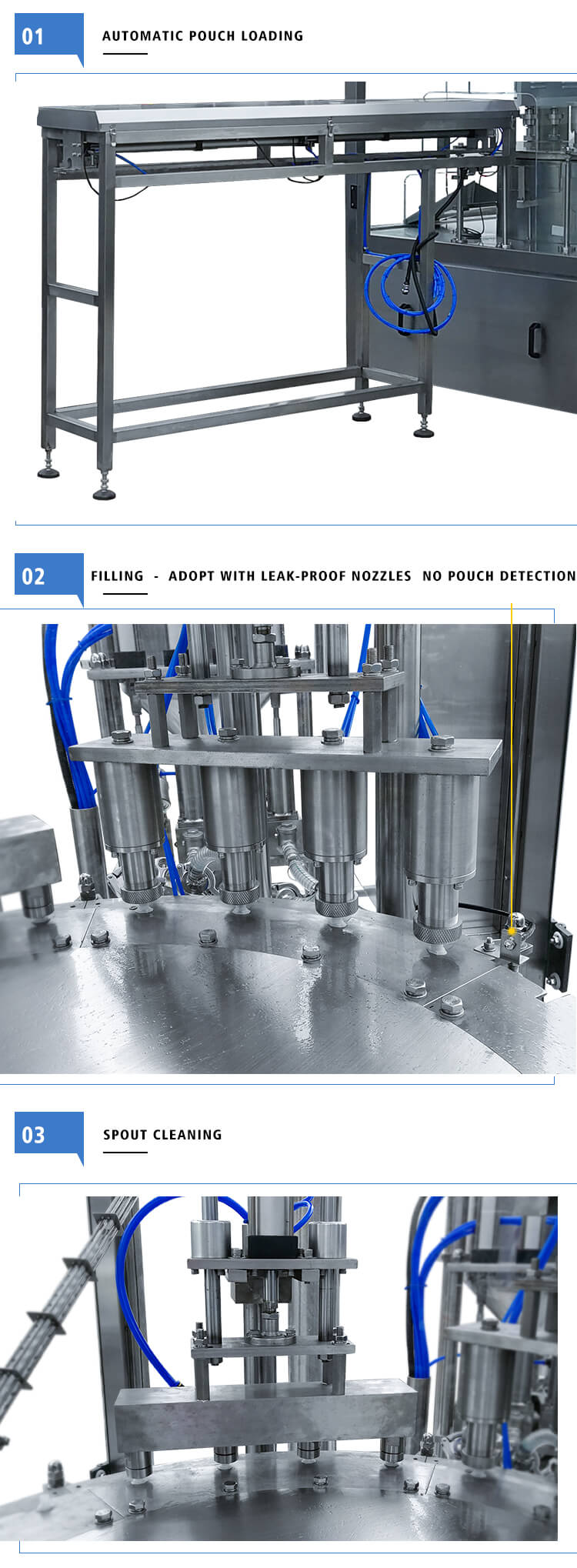

- Pouch loading

- Printing – printing machine required, optional feature

- No pouch detection

- Vacuum – optional feature

- Filling – adopt with leak-proof nozzles

- Nitrogen flushing – optional feature

- Spout cleaning

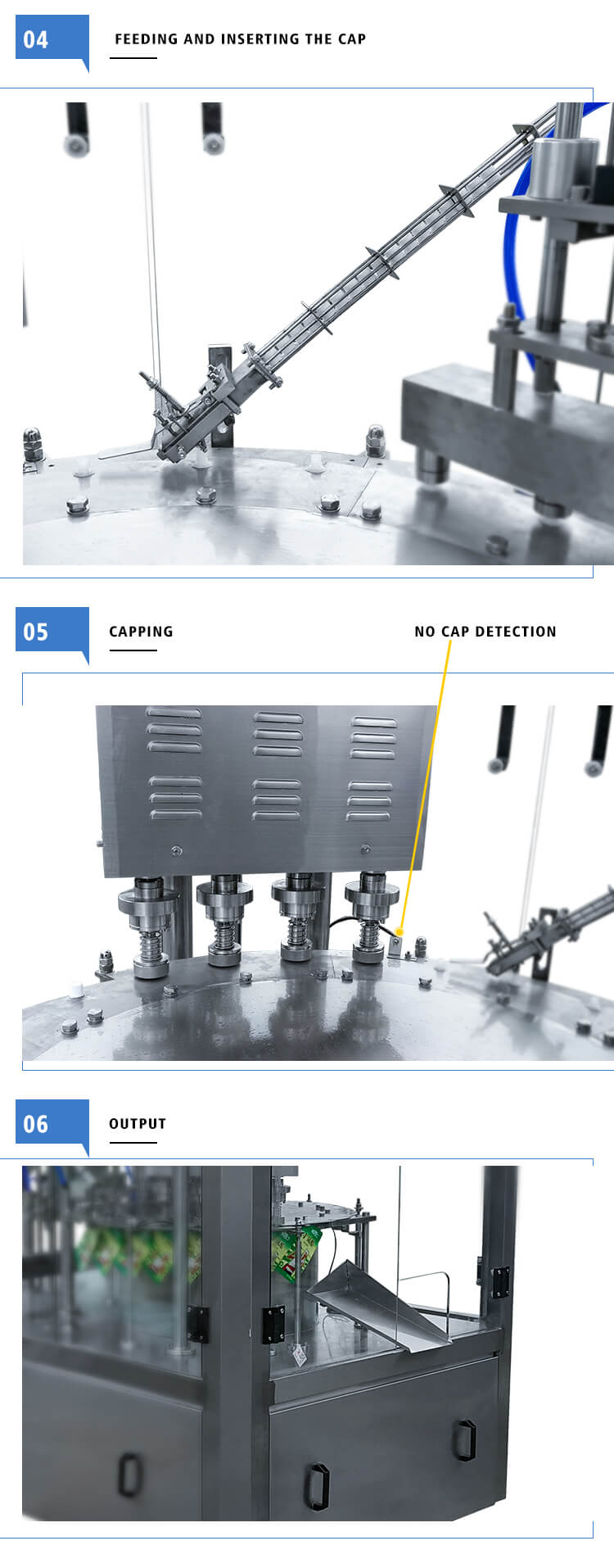

- Feeding and inserting cap

- No cap detection

- Capping

- Discharging

- Transport – conveyor belt required, optional feature

| Model | ZLD-4A |

| Type | Linear type |

| Filling heads | 4heads |

| Capacity | 3600-4000bags/hour |

| Filling volume | 50-500ml(customizable 1-3L) |

| Power | 380V/50HZ |

| Air pressure | 0.65 m³/min |

| Weight | 1400kg |

| Error | ±1% |

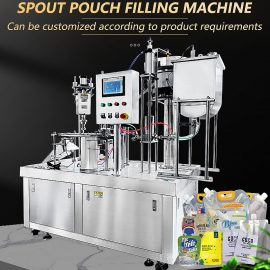

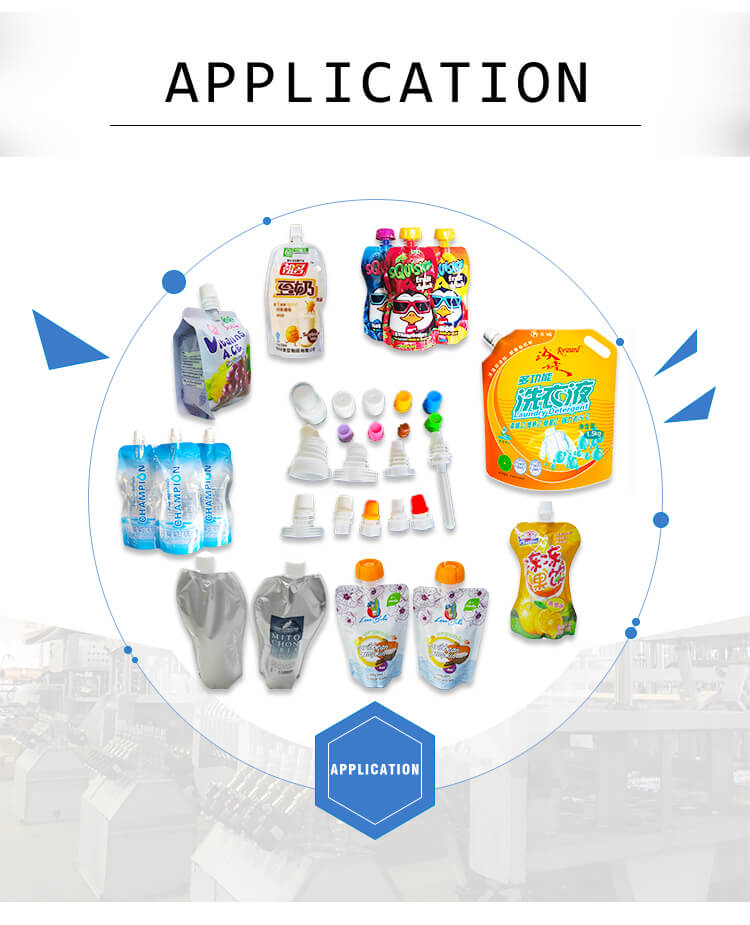

- Widely used for a variety of products, such as jelly, milk, butter, fruit juices, paste, chemical liquid, water and so on.

- High reliability, convenient operation, wide applicability, high performance.

- Import control elements, Schneider, Mitsubishi, Ormon, Siemens, making the system more stable and reliable.

- Contact us to get more details.

Q1: Are you factory or trading company?

A: We are factory and manufacturer. We provide great product and service.

Q2: Where is your factory located? How can I visit your factory?

A: We are located in Shanghai, you can fly to Shanghai Hongqiao airport or Pudong airport. We can pick you up from the airport or your hotel. China. Welcome to visit us!

Q3: How to place an order to us?

A: Just contact us via TraderManager, E-mail, Skype, WhatsApp, WeChat or telephone to confirm the product, We will start to design and manufacture your machine when we receive your down payment.

Q4: What is the payment term?

A: 50% T/T down payment and 50% T/T balance payment before shipping.

Q5: How long is the delivery time?

A: About 7-30 days.

Q6: What is the guarantee and service of machine?

A: One year free warranty, life-long maintenance. We can provide free high quality service online,we also can provide door to door service, this is paid service.